Industry Outlook |

Market space:It is expected that the sludge treatment and disposal capacity will reach 94.267 million tons by 2027.

Policy benefits:Taking the harmless and stable treatment and disposal of sludge as the starting point, and promoting the utilization of sludge resources as the driving force, we aim to build a new pattern of sewage treatment in the new era that reduces pollution, carbon emissions, and enhances efficiency.

Government subsidies:In the "Technical Policy for Sludge Treatment, Disposal, and Pollution Prevention and Control in Urban Sewage Treatment Plants", it is proposed that local governments should further increase the collection and management level of sewage treatment fees. Sewage treatment fees should include the operating costs of sludge treatment and disposal, and be implemented through sewage treatment fees, financial subsidies, and other means to ensure the normal and stable operation of sludge treatment and disposal facilities. Governments at all levels should increase funding for the construction of sludge treatment and disposal facilities, and provide financial and tax incentives for sludge treatment and disposal technologies and equipment that are encouraged for development by the state in accordance with regulations; Establish diversified investment and operation mechanisms, encourage the participation of social funds in the construction and operation of sludge treatment and disposal facilities through various means such as franchising.

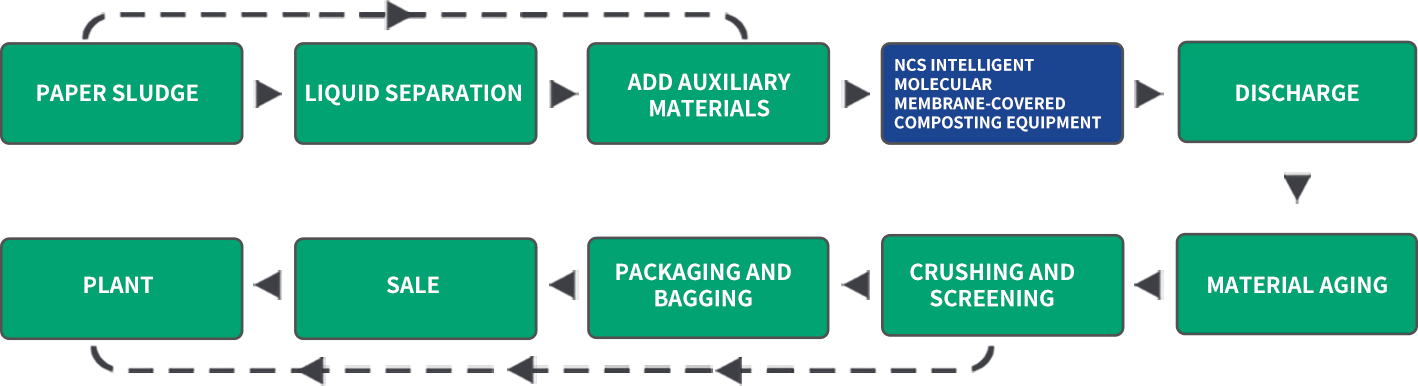

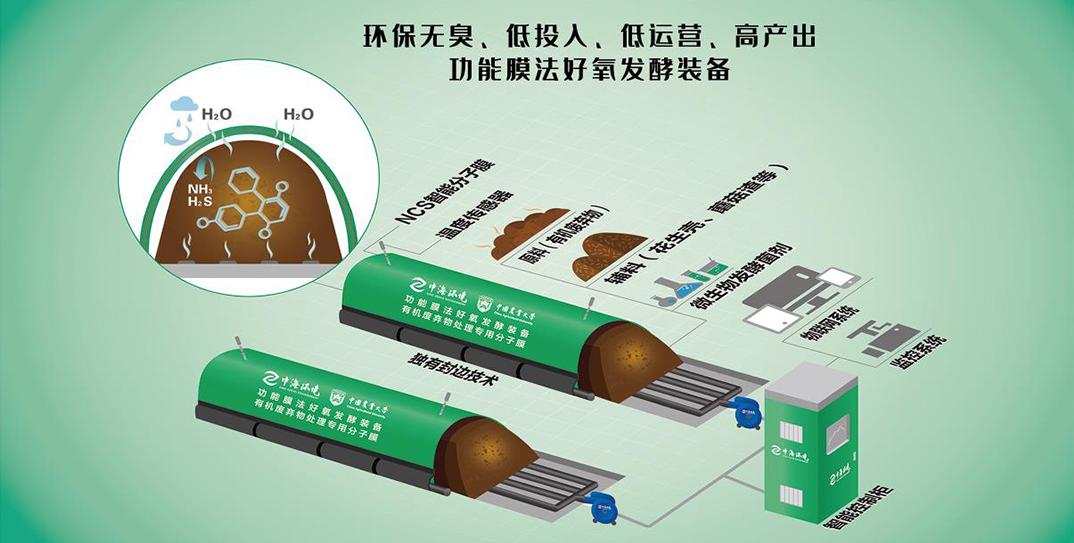

Process flow |

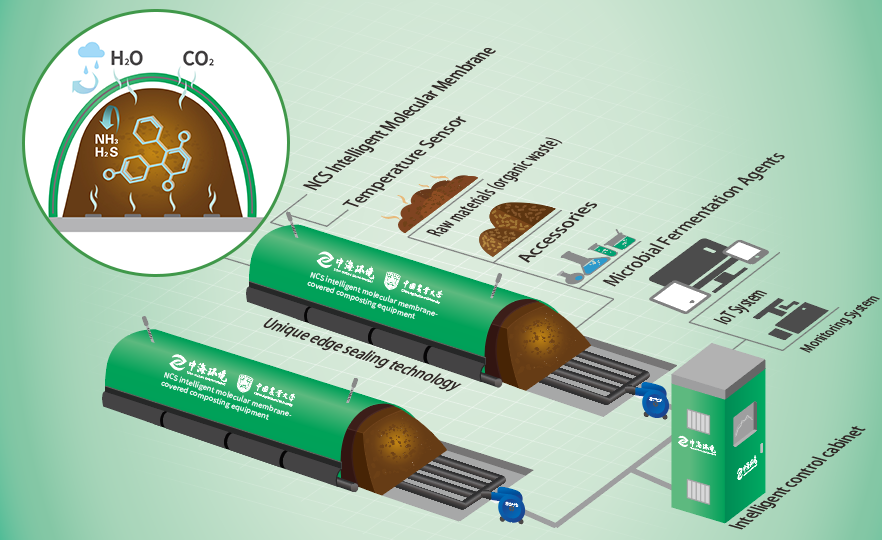

Core Technology - NCS Intelligent Molecular Membrane Fermentation System |

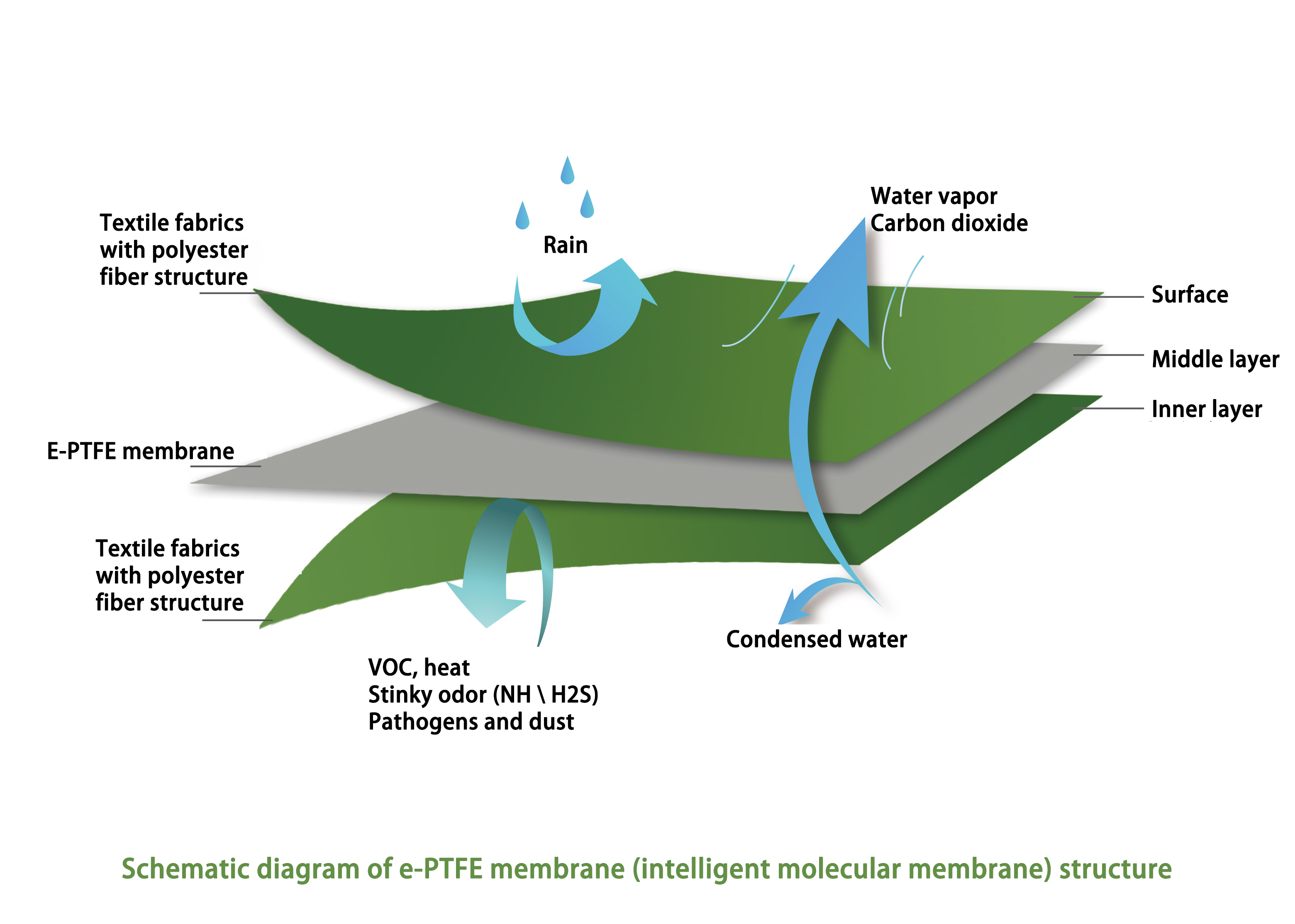

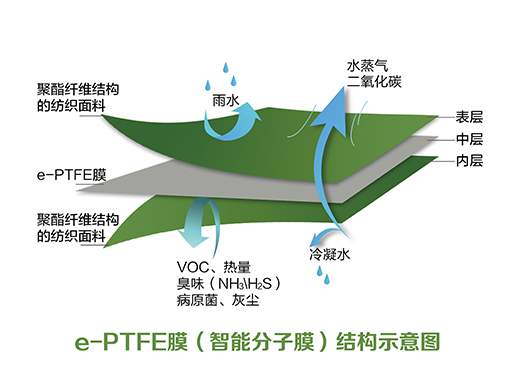

New Material - NCS Molecular Membrane (Polymer Material) |

surface | 1.Anti aging 2.High quality polyester fiber material |

middle-level | 1.E-PTFE membrane 2.Prevent external rainwater 3.Water vapor and air can pass through |

Inner layer | 1.Anti acid and alkali corrosion 2.Isolate odors |

intelligence control system |

● IoT sensing link intelligent control system ● Automated precise temperature control, oxygen supply | ● No manual intervention is required during the fermentation cycle ● 24-hour real-time monitoring of fermentation status through mobile mini program | |

|

| |

24/7 IoT data platform | Independent project composting monitoring system |

Product advantages |

Reduce investment costs by 70%:Compared with traditional processing methods, the total equipment investment is much lower, there is no need for large-scale infrastructure, no need to build factories, and it has efficient processing capabilities.

Reduce operating costs by 60%:Automated operation, no need for flipping, intelligent control, low auxiliary material consumption, and low power consumption. Save labor and operating costs.

Quick water removal in a short period of time:Fermentation can be completed in about 20 days, with sufficient maturity. After fermentation, the material is loose and dry, with a moisture content of only 40%, which can effectively reduce the amount of sludge.

Environmentally friendly and odorless:Polymer functional film materials block odor leakage, effectively reducing the emission of harmful gases such as ammonia, environmentally friendly and odorless, and eliminating secondary pollution.

Processing capacity |

Equipment specifications | Single fermentation cycle | Single sludge treatment capacity | Annual sludge processing capacity | Annual production of nutritious soil |

100m³ | 18±2days | 58t | 1037t | 472t |

200m³ | 18±2days | 116t | 2074t | 944t |

300m³ | 18±2days | 174t | 3111t | 1416t |

400m³ | 18±2days | 232t | 4148t | 1888t |

Project Case |

|

|

| ||

Paper making sludge treatment project in Shandong region | Fermentation materials are piled into the tank | Fermentation materials are piled into the tank |

Industry Outlook |

Market space:It is expected that the sludge treatment and disposal capacity will reach 94.267 million tons by 2027.

Policy benefits:Taking the harmless and stable treatment and disposal of sludge as the starting point, and promoting the utilization of sludge resources as the driving force, we aim to build a new pattern of sewage treatment in the new era that reduces pollution, carbon emissions, and enhances efficiency.

Government subsidies:In the "Technical Policy for Sludge Treatment, Disposal, and Pollution Prevention and Control in Urban Sewage Treatment Plants", it is proposed that local governments should further increase the collection and management level of sewage treatment fees. Sewage treatment fees should include the operating costs of sludge treatment and disposal, and be implemented through sewage treatment fees, financial subsidies, and other means to ensure the normal and stable operation of sludge treatment and disposal facilities. Governments at all levels should increase funding for the construction of sludge treatment and disposal facilities, and provide financial and tax incentives for sludge treatment and disposal technologies and equipment that are encouraged for development by the state in accordance with regulations; Establish diversified investment and operation mechanisms, encourage the participation of social funds in the construction and operation of sludge treatment and disposal facilities through various means such as franchising.

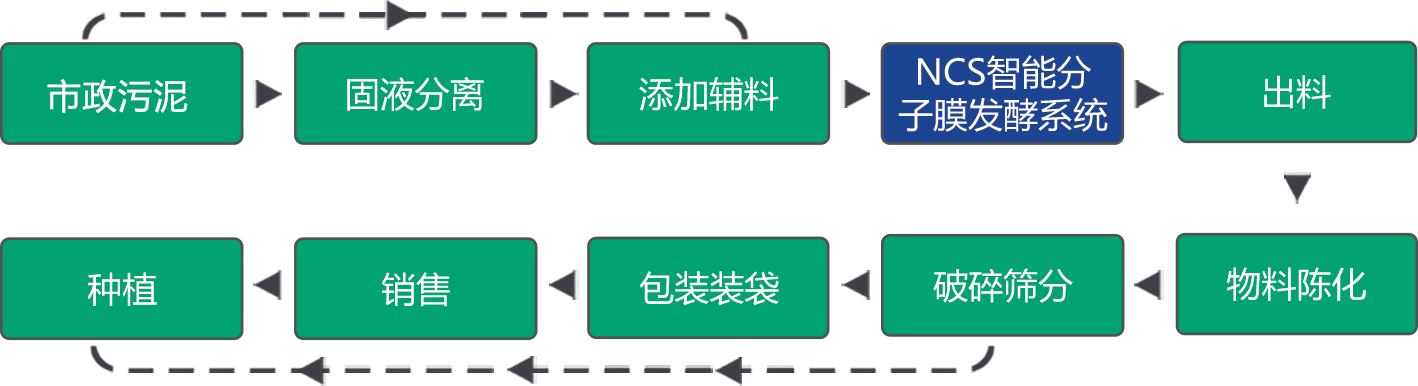

Process flow |

Core Technology - NCS Intelligent Molecular Membrane Fermentation System |

New Material - NCS Molecular Membrane (Polymer Material) |

surface | 1.Anti aging 2.High quality polyester fiber material |

middle-level | 1.E-PTFE membrane 2.Prevent external rainwater 3.Water vapor and air can pass through |

Inner layer | 1.Anti acid and alkali corrosion 2.Isolate odors |

intelligence control system |

● IoT sensing link intelligent control system ● Automated precise temperature control, oxygen supply | ● No manual intervention is required during the fermentation cycle ● 24-hour real-time monitoring of fermentation status through mobile mini program | |

|

| |

24/7 IoT data platform | Independent project composting monitoring system |

Product advantages |

Reduce investment costs by 70%:Compared with traditional processing methods, the total equipment investment is low, there is no need for large-scale infrastructure, no need to build factories, and it has efficient processing capabilities.

Reduce operating costs by 60%:Automated operation, no need for flipping, intelligent control, low auxiliary material consumption, and low power consumption. Save labor and operating costs.

Quick water removal in a short period of time:Fermentation can be completed in about 20 days, with sufficient maturity. After fermentation, the material is loose and dry, with a moisture content of only 40%, which can effectively reduce the amount of sludge.

Environmentally friendly and odorless:Polymer functional film materials block odor leakage, effectively reducing the emission of harmful gases such as ammonia, environmentally friendly and odorless, and eliminating secondary pollution.

Processing capacity |

Equipment specifications | Single fermentation cycle | Single sludge treatment capacity | Annual sludge processing capacity | Annual production of nutritious soil |

100m³ | 18±2days | 58t | 1037t | 472t |

200m³ | 18±2days | 116t | 2074t | 944t |

300m³ | 18±2days | 174t | 3111t | 1416t |

400m³ | 18±2days | 232t | 4148t | 1888t |

Project Case |

|

|

| ||

Organic Sludge Treatment Project in Anhui Region | Organic Sludge Treatment Project in Shandong Region | Organic Sludge Treatment Project in Guangdong Region |

Supporting equipment for the entire industry chain |

Solid liquid separation equipment

|

| |

Stacked screw sludge dewatering machine | Plate and frame filter press |

Fermentation auxiliary equipment

|

|

|

| |||

Wall mounted film rolling machine | Self propelled flipping machine | Slot type laminating flipping and throwing machine | Self propelled laminating and flipping machine |

Low cost, low-carbon, fully automatic nutrient soil production line

|

|

|

| |||

Stock bin | Shredder | screening machine | Packer |

400-805-3612

400-805-3612

sinoocean2010@163.com

sinoocean2010@163.com

No. 36 Jinshui Road, Laoshan, Qingdao City

No. 36 Jinshui Road, Laoshan, Qingdao City

Copyright © 2023-2024 Qingdao Zhonghai Environmental Engineering Co., Ltd. Record number:鲁ICP备20013595号