Industry Outlook |

Background:Furfural residue is a biomass waste produced by the hydrolysis of pentose components in corn cobs, corn stalks, rice husks, cottonseed hulls, and agricultural by-products to produce furfural. Furfural residue, as a waste generated during biomass hydrolysis, has a high salt content and is acidic. Currently, most furfural residues are treated by stacking or digging pits for dumping, which causes varying degrees of pollution to the atmosphere, soil, and rivers due to their large accumulation. But what few people know is that furfural residue is a waste resource, which is relatively easy to obtain and has a low cost of use. As a biomass waste, it contains a large amount of cellulose, hemicellulose, and lignin, which can be recycled and turned into treasure. It can reduce pollution while generating reuse value.

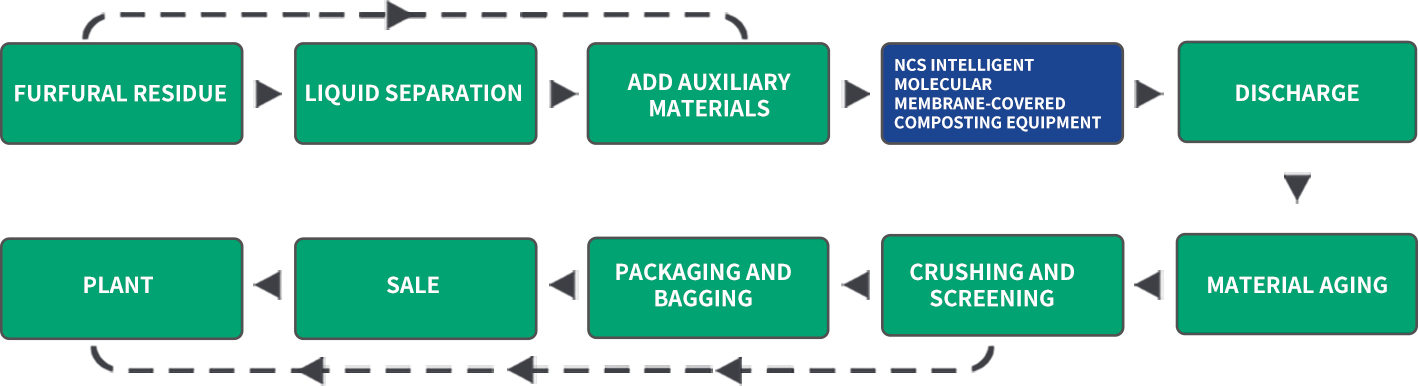

Process flow |

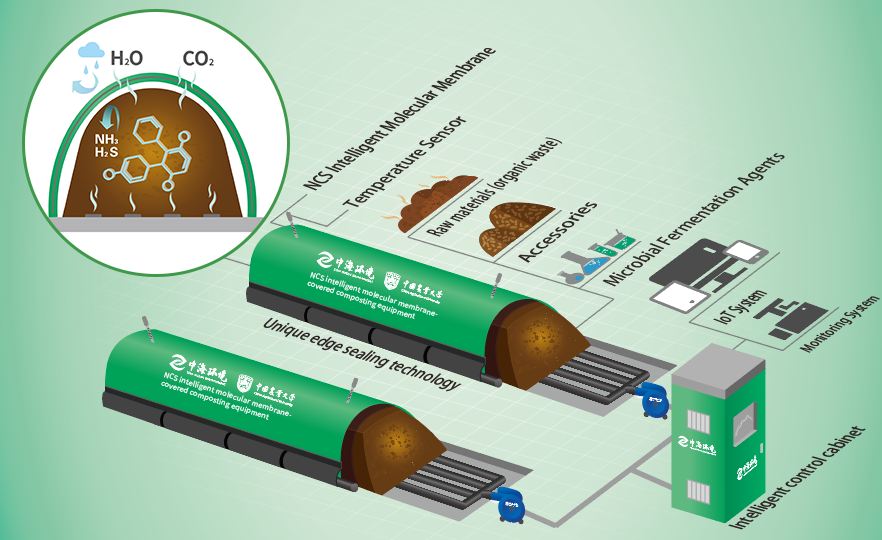

core technology |

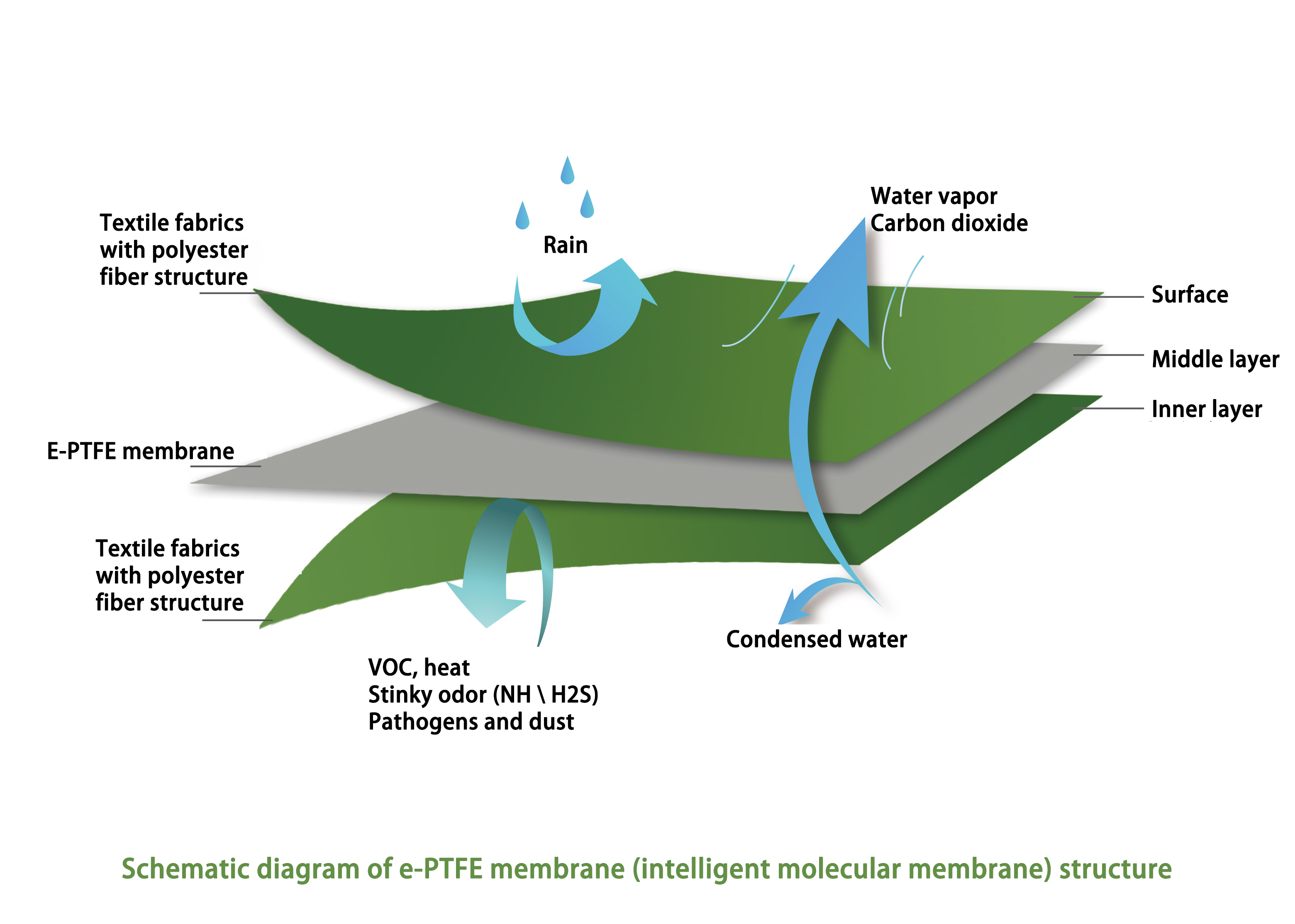

New Material - NCS Molecular Membrane (Polymer Material) |

Surface | 1.Anti aging 2.High quality polyester fiber material |

middle-level | 1.E-PTFE membrane 2.Prevent external rainwater 3.Water vapor and air can pass through |

Inner layer | 1.Anti acid and alkali corrosion 2.Isolate odors |

Intelligence control system |

● IoT sensing link intelligent control system ● Automated precise temperature control, oxygen supply | ● No manual intervention is required during the fermentation cycle ● 24-hour real-time monitoring of fermentation status through mobile mini program | |

|

| |

24/7 IoT data platform | Independent project composting monitoring system |

Product advantages |

● Advantage 1: Reduce investment costs by 70%. Compared with traditional processing methods, the total equipment investment is low, there is no need for large-scale infrastructure, no need to build factories, and it has efficient processing capabilities.

● Advantage 2: Reduce operating costs by 60%. Automated operation, no need for flipping, intelligent control, saving labor and operating costs.

● Advantage 3: With a harmless degree of up to 97%, it can eliminate pests, diseases, and eggs in the material through high temperature.

● Advantage 4: Good odor barrier effect, no need to build factory buildings. Polymer functional film materials block odor leakage, effectively reducing the emission of harmful gases such as ammonia, environmentally friendly and odorless, and eliminating secondary pollution.

● Advantage 5: Intelligent control and simple operation. Intelligent control system, setting fermentation parameters without manual intervention, automatic fermentation.

Project Case |

|

|

| ||

Furfural residue treatment project in Henan region | Conduct fermentation experiments to ensure fermentation efficiency | Material fermentation completed |

processing capacity |

Equipment specifications | Single fermentation cycle | Single furfural slag treatment capacity | Annual amount of furfural residue treated | Annual production of nutrient rich soil |

100m³ | 18±2days | 58t | 1037t | 472t |

200m³ | 18±2days | 116t | 2074t | 944t |

300m³ | 18±2days | 174t | 3111t | 1416t |

400m³ | 18±2days | 232t | 4148t | 1888t |

Supporting equipment for the entire industry chain |

Fermentation auxiliary equipment

|

|

|

| |||

Self propelled flipping machine | Wall mounted film rolling machine | Slot type laminating flipping and throwing machine | Self propelled laminating and flipping machine |

Low cost, low-carbon, fully automatic nutrient soil production line

|

|

|

| |||

Stock bin | Shredder | Screening Machine | Packer |

Fertilization and returning facilities and equipment

|

| |

Double vertical dragon fertilizer spreader | Double disc fertilizer spreader |

400-805-3612

400-805-3612

sinoocean2010@163.com

sinoocean2010@163.com

No. 36 Jinshui Road, Laoshan, Qingdao City

No. 36 Jinshui Road, Laoshan, Qingdao City

Copyright © 2023-2024 Qingdao Zhonghai Environmental Engineering Co., Ltd. Record number:鲁ICP备20013595号