The ECS membrane intelligent composting box is a small-scale manure storage and composting fermentation equipment independently developed by Qingdao Zhonghai Environmental Engineering Co., Ltd. for the treatment of manure generated by small-scale breeding farms and individual farmers. This technology equipment effectively solves the industry problems of many small-scale breeding farms, scattered breeding farm locations, and generally incomplete environmental protection facilities; Its core technology is the derivative and breakthrough of NCS intelligent molecular film covered composting technology.

ECS environmental composting bin

Product video |

Solution process |

Finished product composition |

Main equipment: The equipment casing is divided into two types: PP material and carbon steel material, which are corrosion-resistant and moisture-proof, and have insulation function.

NCS Intelligent Molecular Membrane: The top covered functional membrane material is a specialized e-PTFE membrane material with specially designed micropores. By utilizing its selective permeability, water vapor and carbon dioxide generated during fermentation can diffuse out of the microporous structure of the functional membrane, while external liquid water (rainwater, snow water) cannot enter the membrane. Through active ventilation, a micro positive pressure inner cavity is formed inside the fermentation chamber, thereby maintaining the balance of air flow inside and outside the fermentation box, achieving a relatively constant climate environment, ensuring that aerobic fermentation proceeds more fully and thoroughly, and pathogenic microorganisms are effectively killed; The odor substances generated during fermentation, such as ammonia, can dissolve in the water vapor inside the membrane and condense into the pile, effectively reducing odor emissions and nitrogen loss, and helping to improve the nitrogen content of organic fertilizers and compost quality.

Micro pressure air supply system: Through scientific calculation of formulas and comprehensive technical parameters such as membrane resistance, stack size, and material properties, design matching fans, pipeline connections, air hole layout, and air volume configuration to meet the oxygen supply for aerobic fermentation of different stacks.

Leachate collection system: composed of filter screens, collection tanks, and valves, used to collect organic wastewater generated during the fermentation process, achieve rapid water removal, maintain a dry and hygienic fermentation environment, reduce bacterial growth, and prevent secondary pollution during the entire fermentation process. It helps to meet environmental standards and carry out animal epidemic prevention work in the breeding farm.

Intelligent control system: Real time collection of environmental parameters such as temperature, humidity, oxygen concentration, pH value, as well as fermentation material color, odor and other information through sensing devices, establishing a large database of factors affecting the fermentation pile and a processing control platform; By adopting a PLC control system, the mobile cloud configuration APP can be integrated with the on-site automatic control system and equipment terminals. Real time monitoring data combined with expert remote guidance can be used to remotely control the equipment and achieve 24-hour unmanned operation. Real time adjustment of equipment operating parameters can be achieved to achieve intelligent and automated fermentation process control, reducing the labor cost of equipment that requires continuous or intermittent operation.

Solution process |

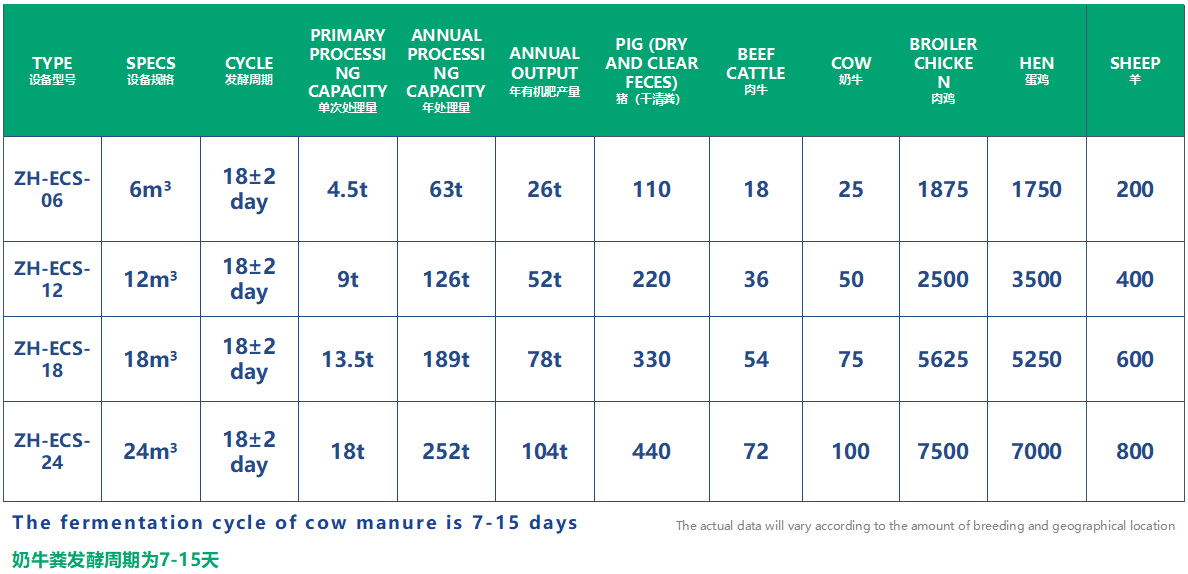

Technical Parameter |

Product advantages |

·No need for civil engineering: Outdoor operation does not require the construction of a factory building.

·Environmental protection and odor isolation: The fermentation environment is sealed and insulated, anti-corrosion and moisture-proof, sturdy and durable, with three layers of film material for environmental protection and odor isolation.

·Flexible and movable: Integrated design, no installation required, saving time and effort.

·Fully automated operation: no need for flipping, static fermentation, no need for manual intervention.

·Good fermentation effect: Good fermentation effect, high nitrogen content, and resource utilization.

·Low investment cost: Low equipment cost, no need for flipping, intelligent control, saving manpower.

·Equipped with a special insulation layer: a special insulation layer that quickly reaches the fermentation temperature.

·Wide applicability: Suitable for organic waste such as livestock and poultry manure, kitchen waste, straw, vegetables, organic sludge, and garden waste.

Project Case |

400-805-3612

400-805-3612

sinoocean2010@163.com

sinoocean2010@163.com

No. 36 Jinshui Road, Laoshan, Qingdao City

No. 36 Jinshui Road, Laoshan, Qingdao City

Copyright © 2023-2024 Qingdao Zhonghai Environmental Engineering Co., Ltd. Record number:鲁ICP备20013595号