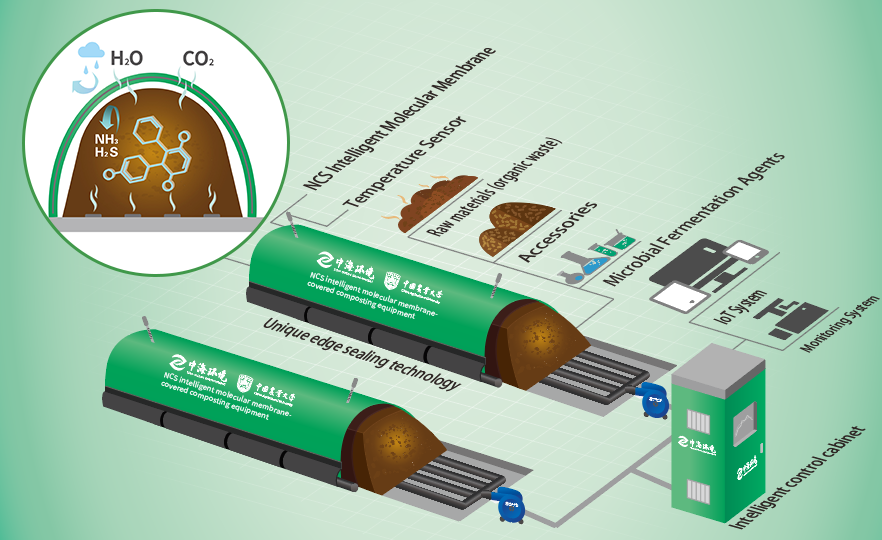

NCS intelligent molecular membrane fermentation technology is an organic waste treatment technology that integrates NCS polymer membrane, sensors, micro pressure air supply technology, intelligent control, microorganisms and other technologies for fermentation and composting. It can simultaneously meet the requirements of environmental protection, odor isolation, low investment cost, low operating cost, intelligent control, meet market demand, and has a good role in reducing emissions and fixing carbon.

NCS Intelligent Molecular Membrane Fermentation System

Product video |

Core technology |

Finished product composition |

NCS intelligent molecular membrane fermentation technology:

NCS intelligent molecular membrane fermentation technology is an organic waste treatment technology that integrates NCS polymer membrane, sensors, intelligent control, microorganisms and other technologies for fermentation and composting. It can simultaneously meet the requirements of environmental protection, odor isolation, low investment cost, low operating cost, intelligent control, easy operation, meet market demand, and has good emission reduction and carbon sequestration effects.

New Material - NCS Molecular Membrane:

It has functions such as waterproofing, moisture permeability, sterilization, and deodorization, which can block the influence of rain and snow, prevent odor emissions to the external environment, and reduce nitrogen loss from manure.

Micro pressure air supply system:

The micro pressure air supply system consists of a supply fan, a supply duct, and a computer control end. Lay micro positive pressure air supply ducts and intermittently expose to oxygen for 24 hours. The interior of the pile is in a slightly positive pressure state, which ensures uniform distribution of oxygen, sufficient contact between air and fermented materials, avoids the formation of anaerobic zones, and achieves good uniform fermentation effect.

Intelligent control system:

The intelligent control system intelligently adjusts the air supply rhythm through the temperature data transmitted back from the stack, keeping the stack in the optimal fermentation state without the need for manual supervision, and the entire process is intelligently controlled.

Waste mixing formula:

composed of a filter screen, a collection tank, and a valve, used to collect organic wastewater generated during the fermentation process, achieve rapid water removal, maintain a dry and hygienic fermentation environment, reduce bacterial growth, and prevent secondary pollution throughout the fermentation process. It helps to meet environmental standards and carry out animal epidemic prevention work in the breeding farm.

New materials |

After strict odor detection:

After professional testing, all test results meet environmental standards;

Ammonia detection is: ≤ 1.0mg/m ³

Hydrogen sulfide: none

Odor concentration:<10 (dimensionless)

NCS membrane material technology research and development:

NCS intelligent molecular membrane has undergone 8 generations of research and development, and has launched 6 membrane materials for practical application effects in different environments.

Different membrane materials are equipped for different fermentation materials and regions, and fermentation can also be carried out normally in extremely cold/hot regions.

NCS membrane material self-produced:

Establish a production base for NCS intelligent molecular membrane fermentation system, independently produce, and control the entire process from raw material procurement, flat desizing, drying and stretching, membrane material composite to product molding, achieving a high degree of integration between equipment and technology.

Technical Comparison |

NCS intelligent molecular membrane-covered composting equipment | Vertical fermentation tank | Flipping compost | |

Operating mode | Build a pile at once, Intermittent micro oxygen exposure | Continuous stirring, Strong aeration | Timed flipping and throwing |

In production | Outdoor, enclosed | Sealed inside the tank | Building a factory and opening up |

Safety effect | Up to 70 ℃, Good inactivation effect on grass seeds and pathogens | Up to 70 ℃, Large nitrogen loss | Up to 60 ℃, Incomplete eradication of insect and grass seeds |

Fermentation time | 20 ± 5 days | 15 Days | 30-60 days |

Processing cost (including auxiliary materials) | About 120 ¥/ton | About 300 yuan/ton | About 200 yuan/ton |

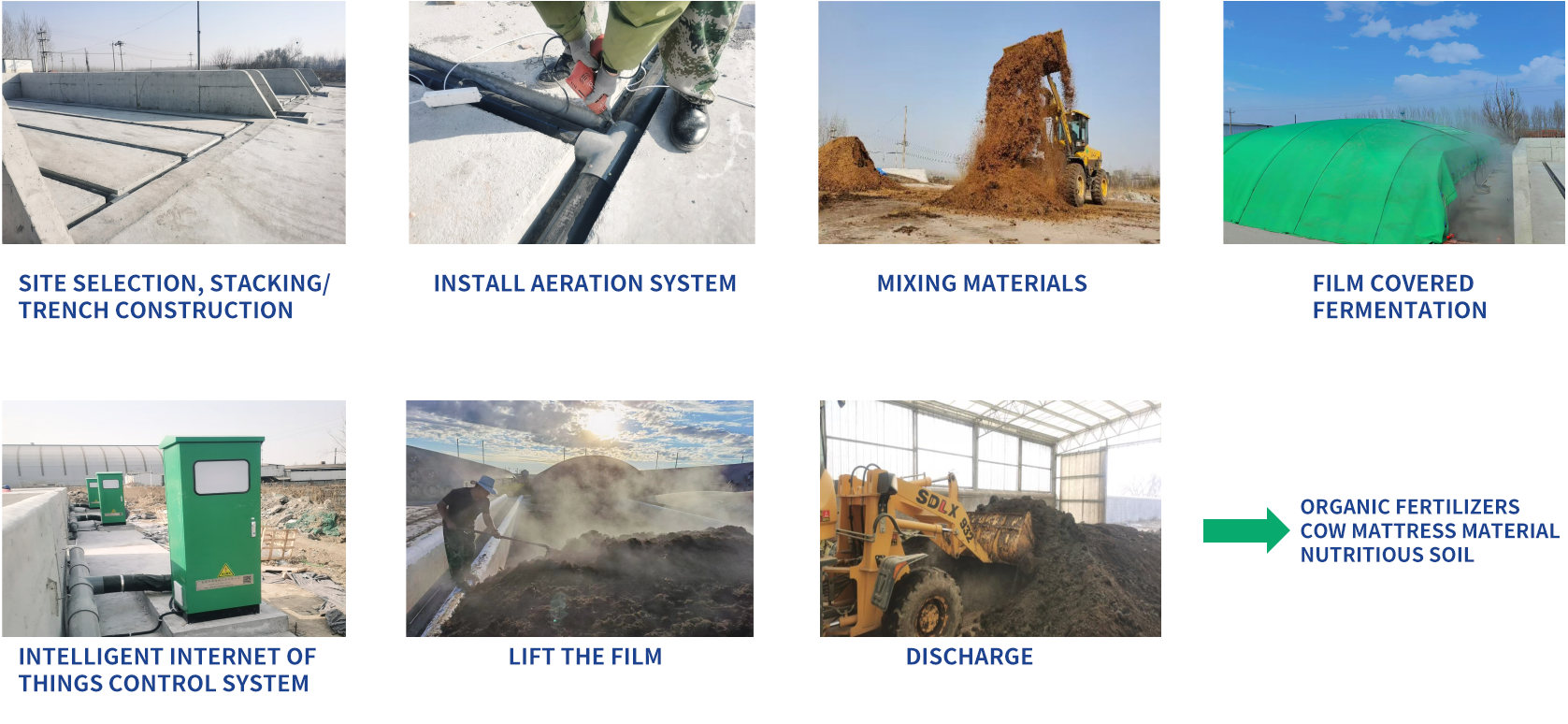

Solution process |

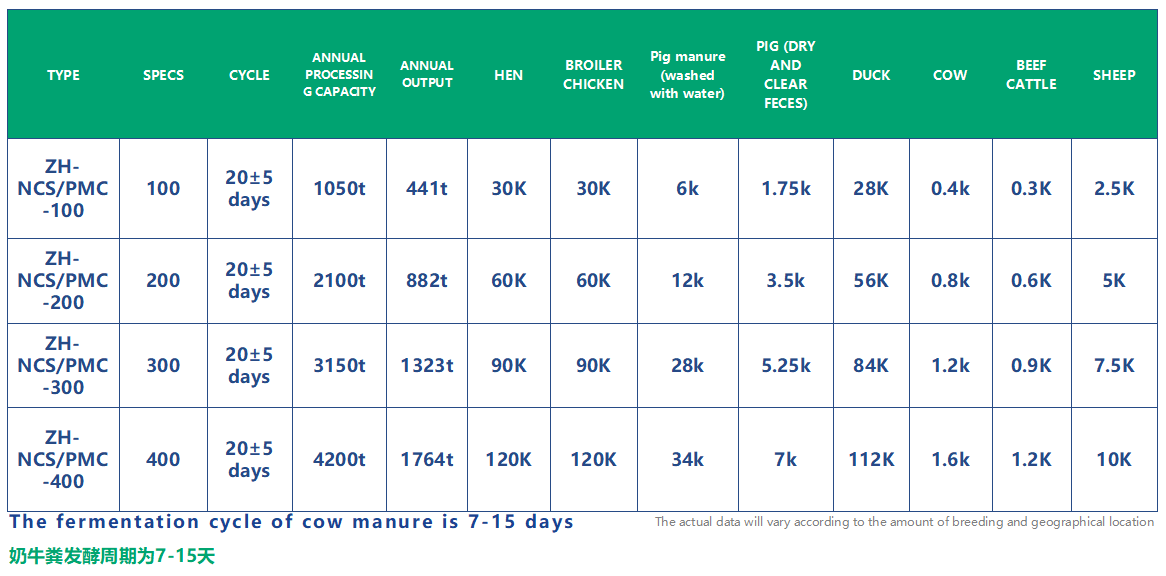

Technical Parameter |

Product advantages |

·Advantage 1: Reduce investment costs by 70%. Compared with traditional processing methods, the total equipment investment is low, there is no need for large-scale infrastructure, no need to build factories, and it has efficient processing capabilities.

·Advantage 2: Reduce operating costs by 60%. Automated operation, no need for flipping, intelligent control, saving labor and operating costs.

·Advantage 3: With a harmless degree of up to 97%, it can eliminate pests, diseases, and eggs in the material through high temperature.

·Advantage 4: Good odor barrier effect, no need to build factory buildings. Polymer functional film materials block odor leakage, effectively reducing the emission of harmful gases such as ammonia, environmentally friendly and odorless, and eliminating secondary pollution.

·Advantage 5: Intelligent control and simple operation. Intelligent control system, setting fermentation parameters without manual intervention, automatic fermentation.

Project Case |

400-805-3612

400-805-3612

sinoocean2010@163.com

sinoocean2010@163.com

No. 36 Jinshui Road, Laoshan, Qingdao City

No. 36 Jinshui Road, Laoshan, Qingdao City

Copyright © 2023-2024 Qingdao Zhonghai Environmental Engineering Co., Ltd. Record number:鲁ICP备20013595号