At a municipal sludge disposal plant in Anhui, up to 60 tons of municipal sludge needs to be treated at the sewage purification station every day. Sludge treatment has always been a headache, there are three traditional sludge treatment methods, landfill method, incineration method, dry method, and these methods are difficult to meet the environmental protection standards, high processing costs.

To this end, the person in charge of the project conducted multiple research and comparison, and learned about the professionalism and rich experience of Zhonghai Environment for sludge treatment technology, and finally chose to cooperate with Zhonghai Environment. According to the actual situation of the project, Zhonghai Environment designed the whole industrial chain solution of sludge treatment, and transformed the municipal sludge into nutritious soil while realizing stabilization, harmfulness and reduction, and also generated certain benefits.

Project profile

Project name: Qingdao Zhonghai Environment Anhui Municipal sludge treatment project

Compost fermentation technology: NCS intelligent molecular membrane aerobic compost technology

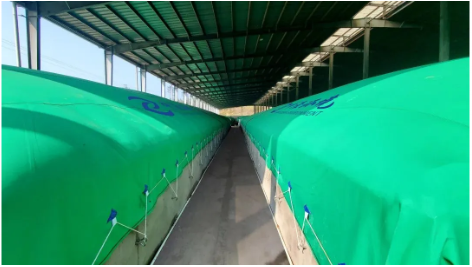

Equipment specifications: 300m³ x20 sets

Fermentation raw material: municipal sludge

Fermentation accessories: corn stalk, wood ash

Fermentation cycle: 13-18 days

Feed water content: 60%-80%

Discharge water content: 30%-40%

End product: nutrient soil

Walk into the project

Sludge treatment site

According to the person in charge of the site said: "According to the design plan of China Sea Environment professional and technical personnel, according to the process, the municipal sludge will first carry out solid-liquid separation, remove excess water through solid-liquid separation equipment, the dehydrated municipal sludge will add the corresponding straw, and be transported to the NCS intelligent molecular membrane fermentation system for harmless treatment by forklift." In the whole process, the municipal sludge will not produce any pollution to the environment, so we can not smell any odor. After high temperature fermentation, the pathogens and harmful substances hidden in the sludge will be all eliminated, so that the sludge can be harmless. "The fermented nutrient soil passes through the nutrient soil processing line, is screened and packaged, and can be sold in the market."

NCS intelligent molecular membrane fermentation system adopts high temperature aerobic fermentation process, which refers to the process of decomposing organic matter in sludge and transforming it into stable humus under aerobic conditions. After aerobic fermentation, the moisture content of the sludge can be reduced to 30%-40%, and the dehydrated sludge can be reduced. In addition, aerobic fermentation of sludge can solve the problem of resource utilization, and nutrient soil can be used in landscaping, flower planting, and land restoration of abandoned sites. Whether from the perspective of economic cost, or focusing on low-carbon economy, recycling, sludge fermentation process is suitable for most areas, low cost investment, but also to avoid environmental pollution.

Technological advantage

1, economical and applicable: the investment cost is reduced by 70%, compared with traditional treatment methods, the total investment of equipment is low, there is no need for large-scale infrastructure, no need to build factories, and there is efficient processing capacity. Operating costs are reduced by 60%, automatic operation, no need to flip, intelligent control, low power consumption, saving labor and operating costs.

2, high fermentation efficiency: the fermentation cycle is only 15-25 days, the moisture content of 80% of the sludge is reduced to 30%-40% of the moisture content, adding aerator and blower and other equipment to help improve the fermentation efficiency, efficiently reduce the sludge moisture content, shorten the fermentation cycle; Using the static fermentation process of tank, the production efficiency is increased by 30%, and the average sludge treatment amount per tank is 300 tons.

3, the fermentation effect is good: diseased eggs and other harmful substances in the nutrient soil are effectively killed, while retaining the nutrients required by the plant nitrogen, phosphorus, potassium, sludge finished products dry, fine, clear particles, high organic matter content and in line with national standards, fertilizer efficiency is good.

The fermented nutrient soil is used for horticultural product cultivation, flower cultivation, nursery cultivation, landscaping or soil improvement, mine restoration and other purposes. In strict accordance with the relevant national standards, the "sludge GB/T 23486-2009 for Municipal sewage Treatment plant sludge disposal garden greening" requirements: the treated sludge is used for the construction and maintenance process of urban green space system or suburban forest land, generally used as medium soil, soil improvement materials, and can also be used as raw materials for making organic fertilizer.

Sludge's "counter-attack" journey is a green revolution about environmental protection, technology and resource recycling. It reminds us that behind every drop of sewage lies the possibility of life. Under the light of science and technology, once waste can be regenerated and become a valuable resource that nourishes the earth. This revolution has not only improved the urban environment, but also opened up a new way for environmental protection. Let us look forward to a more green and sustainable future, growing quietly in every inch of the soil where the sludge "counterattack" transforms.

400-805-3612

400-805-3612

sinoocean2010@163.com

sinoocean2010@163.com

No. 36 Jinshui Road, Laoshan, Qingdao City

No. 36 Jinshui Road, Laoshan, Qingdao City

Copyright © 2023-2024 Qingdao Zhonghai Environmental Engineering Co., Ltd. Record number:鲁ICP备20013595号