Recently, the "International Poultry" magazine reporter on the "14th Five-Year" national agricultural green development Plan since the implementation of the Ministry of Agriculture and rural areas focused on fertilizer and pesticide reduction and efficiency, agricultural waste resource utilization, agricultural and rural emission reduction and carbon sequestration policies and indicators, which will bring new opportunities and challenges to the efficient utilization of poultry waste resources? And how to innovate in the technical level of chicken manure treatment, so as to achieve the simultaneous promotion of economic benefits, environmental benefits and social benefits? With these questions, the reporter of "International Poultry" magazine interviewed Mr. Wei Zhengli, general manager of solid waste Division of Qingdao Zhonghai Environmental Engineering Co., LTD., and discussed the unified cooperation and integration development path of the utilization of livestock and poultry waste resources and the high-quality and sustainable development of the poultry industry.

Wei Zhengli: Solving the problem of the last kilometer of manure return to the field is the key

At present, the livestock and poultry industry in ensuring the stable supply of meat, eggs, milk at the same time, also produced a large number of livestock and poultry manure, so far most of the domestic livestock and poultry manure has not been reasonable and effective treatment and utilization, has gradually become a major problem in the process of rural environmental pollution control.

Mr. Wei Zhengli said that most areas of China have high soil fecal pollution carrying potential, which is conducive to the recycling of livestock and poultry manure in situ farmland. In the northeast of China, the degradation of black land is serious, the planting structure is single, and the dominant crop has a large demand for nitrogen and phosphorus. North China is a large grain-growing area in China. Most soil layers are thick and nutrient poor. The northwest region has deep soil layer, lack of organic matter and strong adsorption capacity of soil. The planting system in southwest China is varied, mostly purple soil, rich in phosphorus and potassium but lacking in nitrogen. The cultivation intensity in South China is large, the multiple cropping index is high, the crops are two to three times a year, and the land needs a large amount of fertilizer. Promoting the combination of breeding and breeding according to local conditions is the key idea of resource recycling of livestock and poultry manure in China.

To this end, the National Livestock Station launched the collection and promotion of practical technologies and typical cases for the utilization of livestock manure in farms (households) below the scale in November 2021, and finally formed the ten main technologies for the utilization of livestock manure in farms (households) below the scale after the organization and recommendation, review and selection, summary and extraction, namely: Compost technology, reactor compost technology, strip compost technology, deep tank ectopic fermentation bed technology, odor reduction technology, fermentation bedding technology, substrate cultivation technology, animal protein transformation technology, storage fermentation technology, anaerobic fermentation technology.

"The most critical problem of animal manure treatment is to solve the last kilometer of manure return to the field, only by opening up the last kilometer, can we really build the industrial chain of animal manure resource recycling." Wei Zhengli believes that to solve this key problem, we need to face three major challenges:

First, due to the possibility of root burning and seedling burning in undecomposed chicken manure, and unfermented or insufficiently fermented chicken manure may contain pathogens such as nematodes, which will bring risks of diseases and pests, there are still prejudices and concerns about the use of organic manure in some regions.

Second, the capital investment of waste treatment equipment and facilities is high and the land area is large, coupled with the poor market operation of livestock and poultry waste, the market mechanism is not perfect, the income of finished products can not cover the cost expenditure, and the enthusiasm of some farmers to participate is low.

Third, the effect of organic fertilizer is slow, the application technology is more complex than chemical fertilizer, the transportation cost is high, and the seasonal restrictions of planting, while the regulatory role of the price mechanism has not been fully played, the price of agricultural products applied organic fertilizer has not been significantly increased than the price of agricultural products applied chemical fertilizer, resulting in the imbalance between the supply and demand of organic fertilizer, sales is very difficult.

To this end, Mr. Wei Zhengli suggested three:

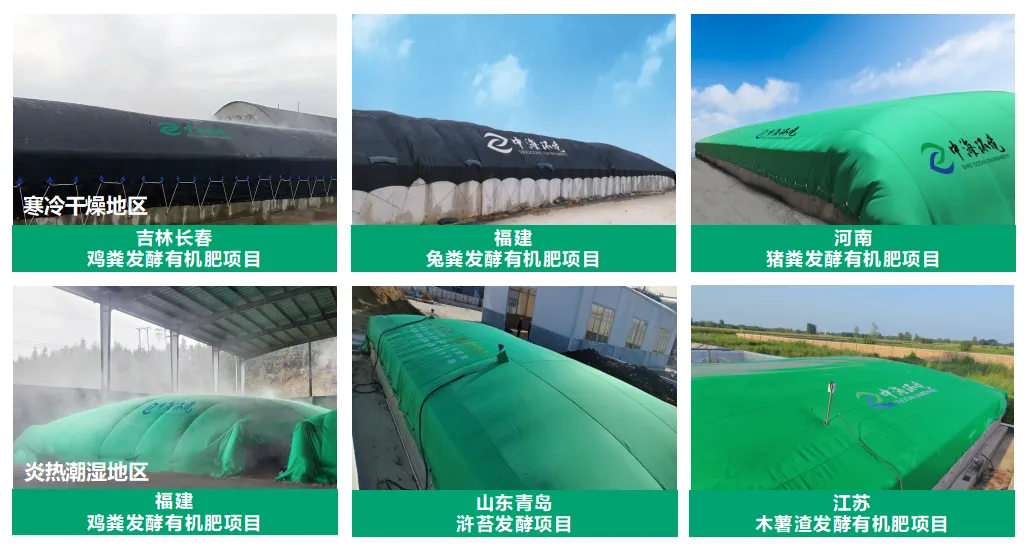

First, continue to upgrade the transformation of equipment, continue to develop and use microbial bacteria to shorten the fermentation cycle, reduce construction and operating costs. For example, the open-air molecular membrane fermentation system reduces the investment cost by about 70% compared to the traditional fermentation system, and the organic fertilizer fermentation only takes 25 to 28 days.

The second is low-cost operation, simplify the processing process, improve the overall level of intelligence, reduce the difficulty of operation, reduce labor costs, and improve the management level.

Third, manure treatment conforms to the actual situation of the local, according to the structure, type and fertilizer use habits of the surrounding planting to choose the most cost-effective and suitable manure treatment process, and timely nearby and local consumption.

By Ma Xiaodi

NCS intelligent molecular membrane fermentation system is a process technology that converts organic waste into organic fertilizer, nutrient soil and cow mattress material for recycling in only 25 to 28 days, which not only reduces the pressure on the environment, but also brings economic benefits and achieves environmental protection gains. The equipment can be used in animal manure, municipal sludge, straw and tail vegetables, kitchen waste and other organic wastes.

And has the following advantages:

1, compared with traditional equipment investment costs reduced by 60%, operating costs reduced by 70%.

2, environmental protection odor, film material rain and snow, can be fermented in the open air, no need to build factories, save investment costs.

3, good fermentation effect, high ammonia content of fertilizer, disease eggs inactivation effect of up to 96%.

4, After 8 generations of research and development, launched 6 membrane materials, better adapt to different fermentation regional environment, different fermentation raw materials, to ensure fermentation effect.

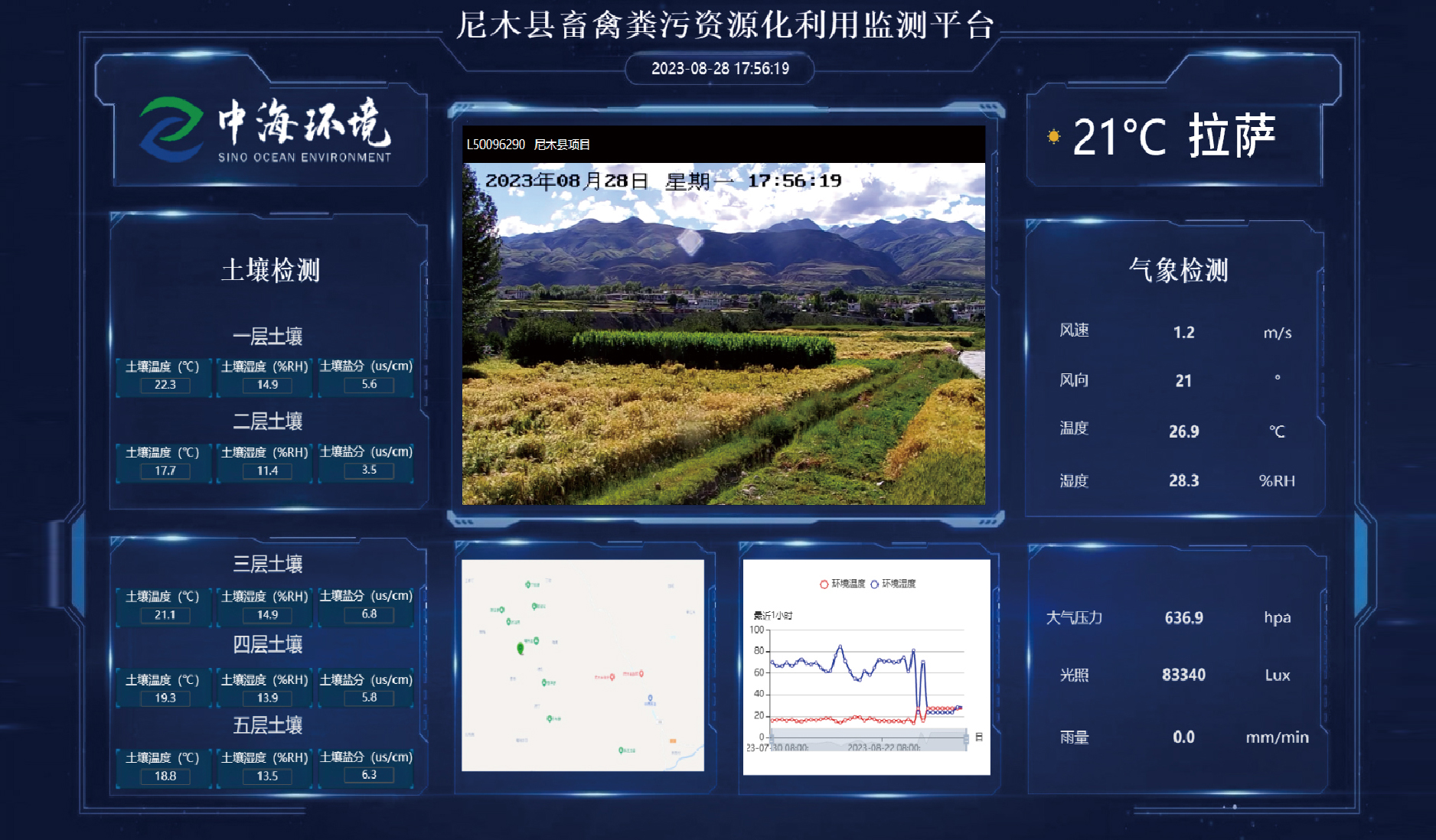

5, intelligent control, fermentation process without manual intervention, automatic fermentation, equipped with mobile APP, online and offline joint control, can understand the on-site fermentation progress without leaving the house.

400-805-3612

400-805-3612

sinoocean2010@163.com

sinoocean2010@163.com

No. 36 Jinshui Road, Laoshan, Qingdao City

No. 36 Jinshui Road, Laoshan, Qingdao City

Copyright © 2023-2024 Qingdao Zhonghai Environmental Engineering Co., Ltd. Record number:鲁ICP备20013595号