Tidings of glad tidings

-- China Sea environment --

NCS intelligent molecular membrane fermentation system was selected

List of Practical Technologies and Demonstration Projects for Ecological and Environmental Protection in 2022

ART.01

Central Association (2022) No. 240

Announcement on the List of Practical Technologies and Demonstration Projects for Ecological and Environmental Protection in 2022 (Publicity Draft)

In order to help fight the battle of pollution prevention and control, promote the coordinated development of pollution reduction and carbon reduction, accelerate the promotion and application of advanced and applicable ecological environmental protection technologies, and enhance the green and low-carbon development level of the ecological environmental protection industry, I will carry out the promotion of practical technologies and demonstration projects for ecological environmental protection in 2022. After recommendation, form review and expert evaluation, 50 practical technologies for ecological and environmental protection and 70 demonstration projects for ecological and environmental protection have been selected, and the List of Practical Technologies and Demonstration Projects for Ecological and Environmental Protection in 2022 (Publicity Draft) has been compiled and formed (see annex), which is now publicized.

NCS intelligent molecular membrane fermentation system

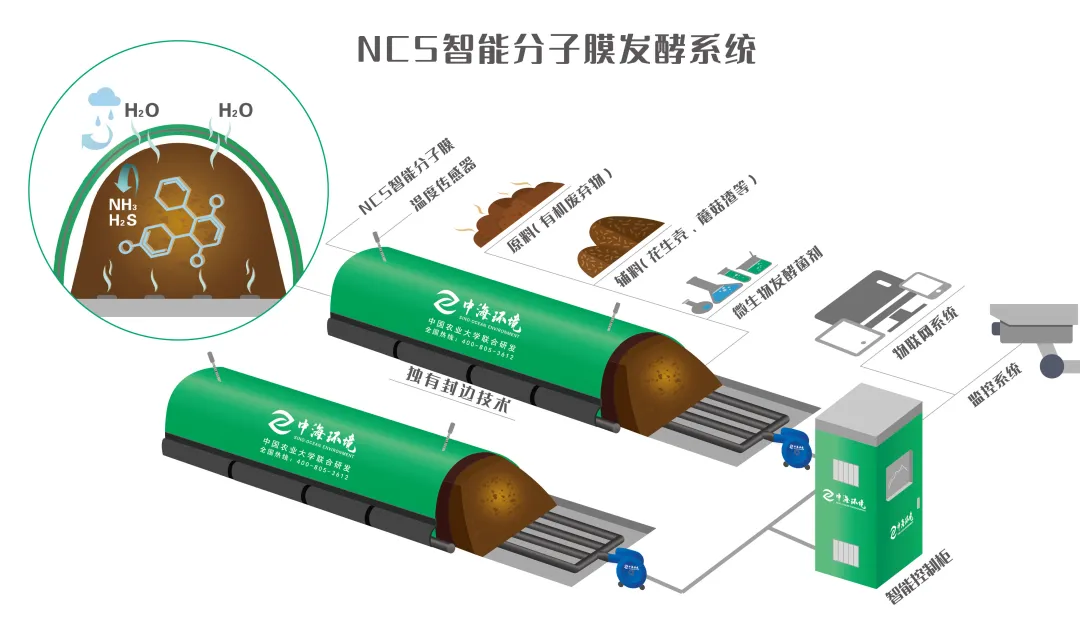

NCS intelligent molecular membrane aerobic composting technology is a technology that uses special functional membrane as a mulch for aerobic fermentation treatment of organic waste. The core of the technology is a functional membrane with special micropores, whose selective permeability function can create a good living environment for aerobic fermentation microorganisms. A micro-positive pressure chamber was formed in the fermentation body through active ventilation, which ensured that the oxygen supply inside the fermentation pile was uniform and sufficient, and established a suitable environment for aerobic fermentation. The water vapor and carbon dioxide produced in fermentation can be diffused from the microporous structure of the functional membrane, maintaining the airflow balance inside and outside the membrane of the fermentation pile, and ensuring that the aerobic fermentation is carried out more fully and thoroughly. Odorous substances such as nitrogen dissolve in the water vapor in the inner layer of the film and fall into the pile, which effectively reduces the emission of odor and nitrogen loss, helps to improve the nitrogen content of organic fertilizer and improve the quality of compost. The high temperature environment formed in the NCS intelligent molecular membrane allows the pathogenic microorganisms to be effectively killed, thus ensuring the harmless level of the fermentation.

Technical core

The core of the technology is a functional membrane with special micropores -NCS intelligent molecular membrane, which is composed of three layers:

Surface: high quality anti-UV anti-aging polyester fiber material;

Intermediate layer: e-PTFE semi-permeable film material with special selective permeability;

Inner layer: polyester fiber material resistant to acid and alkali corrosion. e-PTFE membrane material is the core of NCS intelligent molecular membrane system, the polymer membrane, the fermentation process can produce odor (NH3/H2S), VOC, dust and pathogenic bacteria barrier in the membrane to continue to decompose, but the generated water vapor can be quickly exuded, while the outside liquid water (rain, snow) can not enter the membrane.

Classic project case

Jilin Province NCS membrane fermentation technology treatment of chicken manure project

300 cubic film fermentation equipment 10 sets

During the commissioning period of the project, the average temperature is about -15℃ in winter. During the use of the equipment, the reactor successfully heated up to a temperature above 56℃ on the third day and could be maintained for about 5-15 days. During the whole fermentation process, no secondary pollution was generated, no effluent wastewater was discharged, the concentration of odor discharge met the requirements of environmental assessment, and the moisture content of materials after fermentation could be reduced from 65% to less than 45%. The water in the reactor is mainly discharged in the form of water vapor from the void of the molecular film, and after a certain time of aging, the quality of the product can meet the standard requirements of NY/T-525-2021.

During the operation of this project, the equipment stability and fermentation project are good, no accidents have occurred, and no secondary pollution has occurred during the operation.

Carbon emission reduction effect generated by technology application: This project has 10 sets of equipment with a processing capacity of 300 square meters, and the main energy consumption during operation is the electricity cost of the fan and the fuel and power cost of the forkhoist. After cost accounting, the cost of each output of 1 ton of organic fertilizer is about 15-20 yuan. 30 to 60% less than conventional treatment.

400-805-3612

400-805-3612

sinoocean2010@163.com

sinoocean2010@163.com

No. 36 Jinshui Road, Laoshan, Qingdao City

No. 36 Jinshui Road, Laoshan, Qingdao City

Copyright © 2023-2024 Qingdao Zhonghai Environmental Engineering Co., Ltd. Record number:鲁ICP备20013595号