Recently, environmental protection storms have been set off across the country again, and more than 600 farms in Fujian, Guangdong, Guangxi and other places have been demolished. In addition, affected by the recovery of pig prices, pig breeding related enterprises have also mushroomed across the country.

One side is to dismantle the farm, the other is to build a new breeding enterprise, under the environmental storm, how to solve the environmental problems of breeding enterprises? After investigation, we found that the biggest difficulty is the disposal of feces.

The farm was demolished

The resource utilization of livestock and poultry manure is a connection between planting and breeding, which is related to human, livestock, environmental health and food safety. Local composting and returning of livestock and poultry to the field is the most effective way to solve the pollution of livestock and poultry breeding and improve the quality of soil cultivated land. However, due to the high fermentation temperature in traditional composting, large ammonia emissions are caused. While reducing the efficiency of composting, the emission of harmful gases such as ammonia into the environment also affects the surrounding environment. More than 80% of environmental complaints in livestock and poultry farms are caused by the odor affecting the lives of surrounding residents; At the same time, due to the low nutrient content of livestock and poultry manure, large application amount and high labor cost, the last kilometer of returning land has not been effectively solved. To solve these problems, "NCS membrane composting technology" was introduced.

![]()

NCS membrane composting technology

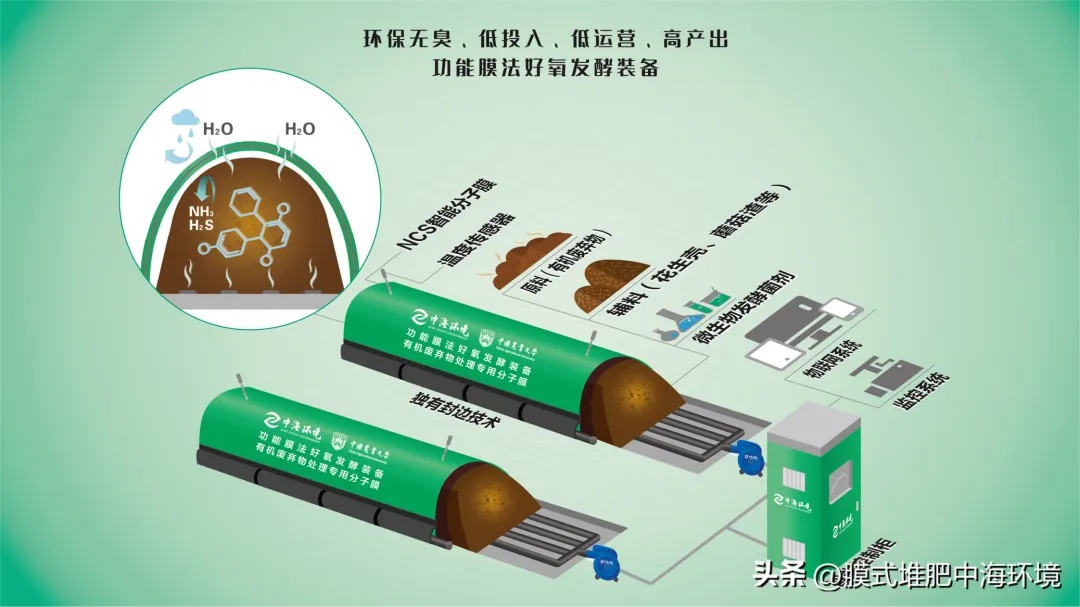

The solid manure film composting technology solves the problems of odor emission and deodorization equipment in general fermentation technology, and realizes ammonia emission reduction. Through the membrane covering, during the composting period, the high temperature above 60℃ is maintained for more than 10 days, thoroughly killing harmful eggs, grass species, pathogenic microorganisms, and protecting the soil environment; The technology does not need to build factories, completely replace buildings such as workshops or sheds, do not need to build fermentation tanks, and greatly reduce the investment cost of livestock farms and waste treatment centers; Energy saving, power consumption per ton of organic fertilizer 2 degrees, reduce operating costs; Remote intelligent control during fermentation, no need to turn the pile frequently, saving labor.

NCS membrane composting technology

The technology is to form a micro-positive pressure "artificial climate box" in the membrane after pretreatment of livestock and poultry manure adding auxiliary materials and microbial decomposition agents, and completely cover the material with nanomembrane. Through intelligent control system, the ventilation oxygen supply process is regulated, microbial metabolism produces high temperature sterilization and insecticide above 60°C-70°C, and discharge harmless substances such as water vapor and CO2. Blocking odor and odor overflow, achieving high temperature fermentation of aerobic microorganisms, transforming livestock and poultry manure into relatively stable humus organic fertilizer raw materials.

NCS membrane composting technology

1. Main composition

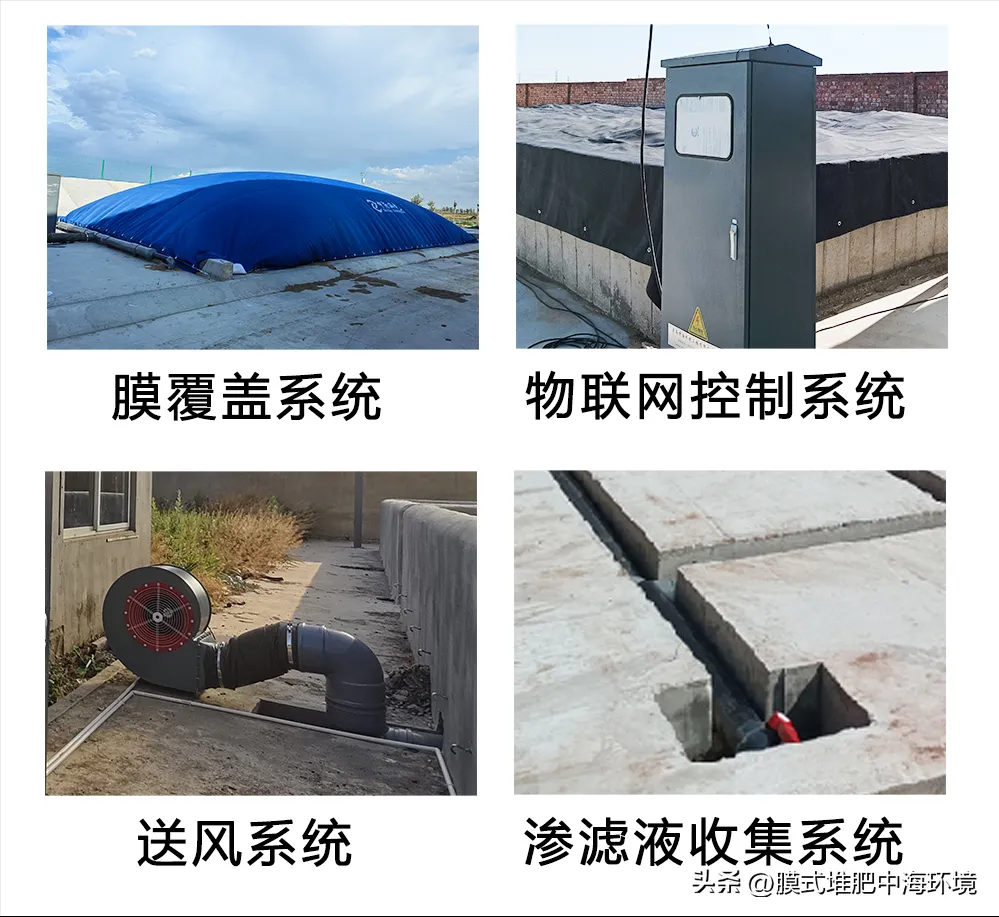

(1) Molecular film, the special three-layer structure of the film material makes it anti-ultraviolet surface aging, anti-mechanical wear, etc., and the service life is as long as 8-10 years;

(2) The ventilation system, including the fan and the air duct, is used to ensure the oxygen inside the pile, and the monitoring system is combined to control the frequency conversion operation of the fan;

(3) Automatic control system, including electronic control system, pressure sensor and temperature sensor. The temperature sensor is a three-point type, which can detect the temperature of different reactor heights, and better the situation inside the reactor body.

NCS membrane composting technology

2, mixed pretreatment

According to the material formulation requirements, the raw materials, auxiliary materials and microbial agents are mixed by mixing equipment and tossing equipment. The moisture content of the mixed compost material is controlled at 55% ~ 65%, that is, grab a handful in the hand, hold it tightly into a group, there is no water between the fingers, and the hand is loosened by touching it gently. According to the different situation of various feces, the selection of mixing equipment is also different.

(1) The water content is 65% and the material with good porosity can be mixed directly with the forklift.

(2) The water content of more than 70% of the material, must be added to the selection of flipping machine for mixing. Such as chicken manure, duck manure and so on.

(3) After wet and dry separation of cow manure, pig manure, only need to control its moisture content, can be built directly without flipping.

NCS membrane composting technology

3. Build a pile

The mixed materials are built in trapezoidal piles. The width of the upper part of the pile body is generally not less than 2/3 of the width of the bottom part of the pile body. The width of the bottom part of the pile body is the design width of the fermentation zone. When building the pile, the material should be uniform and loose to prevent inconsistent material thickness and unequal water content.

NCS membrane composting technology

4. Film covering

The molecular film is completely covered on the reactor body, and the edge of the nanomembrane is compacted by pressing bag or other means to keep the edge of the air leakage.

5. Fermentation

Film fermentation is also called a fermentation, the process includes heating period, high temperature period, cooling period. During the composting process, the fermentation of compost is judged by nose smell. If there is excessive pungent odor such as acid and odor, the water content should be adjusted in time to make it fermented well.

NCS membrane composting technology

NCS membrane composting technology

6. Process parameter control

Composting equipment is used to control composting parameters, including ventilation, temperature and pressure.

(1) Temperature control. During the fermentation process, the temperature change of the pile layer must be measured. The fermentation temperature of the pile should be controlled at 55℃~70℃, and the compost temperature should reach more than 60℃ during the film fermentation cycle, so as to fully decompose.

(2) Through the risk control system. During fermentation, the pressure should be measured. The oxygen concentration in the reactor must be kept above 8% through forced ventilation, and it is appropriate to control it at 10% to 15%.

(3) Moisture control. As the moisture content of compost fermentation gradually decreases, the moisture content should be 35%~45% at the end of film fermentation.

7. Remove the membrane

The fermentation cycle is generally 15-20d. When judging the degree of maturation and terminating the fermentation, the fermentation material will no longer heat up, the film will be removed, and the pile will have no odor and its color will be gray, grayish brown or black.

NCS membrane composting technology

8. Post-processing and utilization

Store the produced decomposed compost in bulk or in bags in a rain-proof place for sale. The decomposed compost can be crushed, screened and further processed.

400-805-3612

400-805-3612

sinoocean2010@163.com

sinoocean2010@163.com

No. 36 Jinshui Road, Laoshan, Qingdao City

No. 36 Jinshui Road, Laoshan, Qingdao City

Copyright © 2023-2024 Qingdao Zhonghai Environmental Engineering Co., Ltd. Record number:鲁ICP备20013595号